Confectioners Sugar Replacement by Swerve Thrive Market

Coating and Systems Food Ingredients Expert

Confectionery Coatings. Blommer offers a wide variety of compound coatings made with specialty vegetable fats to optimize coating performance while delivering the desired flavors. Offered in a variety of flavor profiles, particle size, viscosities and colors to meet your every need. Contact your Blommer Representative to help guide you to the.

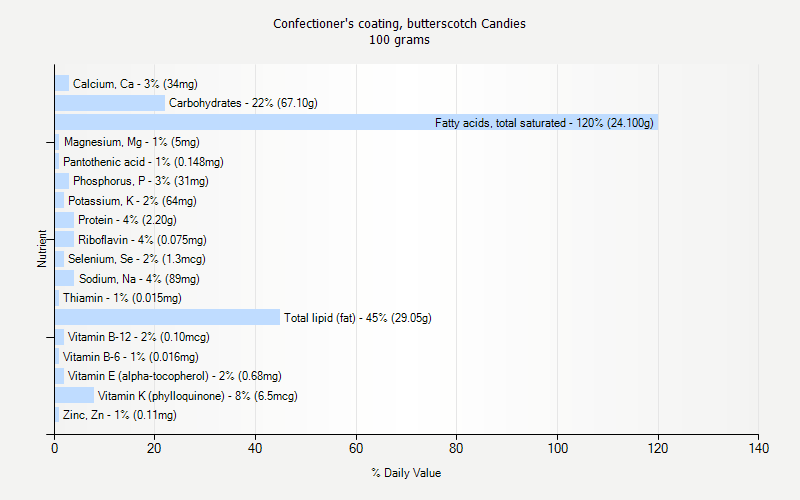

Confectioner's coating, butterscotch Candies nutrition

Confectioners' Sugar: Confectioners' sugar (also known as powdered sugar and icing sugar) is a crucial part of these chocolate crinkle cookies. It is used for coating the cookie dough balls before baking. As the cookies spread and crack during baking, the confectioners' sugar creates a distinctive crinkled appearance on the surface.

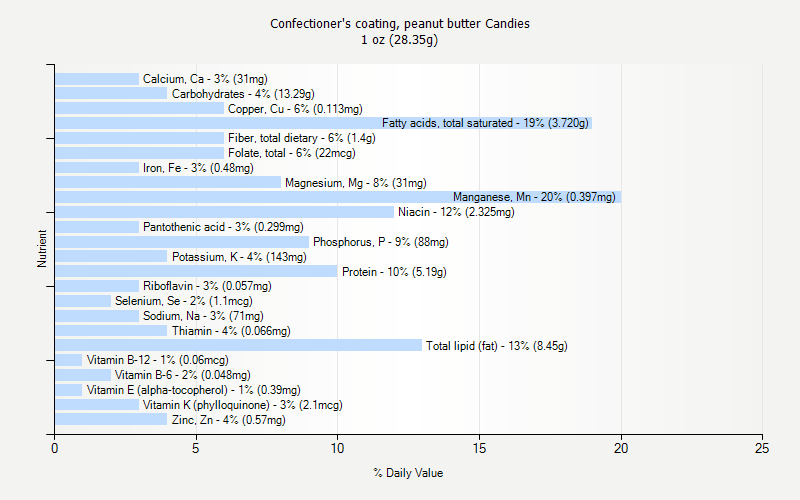

Confectioner's coating, peanut butter Candies nutrition

1. Cover tray with wax paper. 2. Place chocolate chips and shortening in medium heat-proof bowl. In separate large heat-proof bowl, put very warm water (100° to 110° F) to 1-inch depth. Carefully place bowl with chocolate into bowl with water; water should come halfway up side of chocolate bowl. 3. Stir chocolate and shortening constantly.

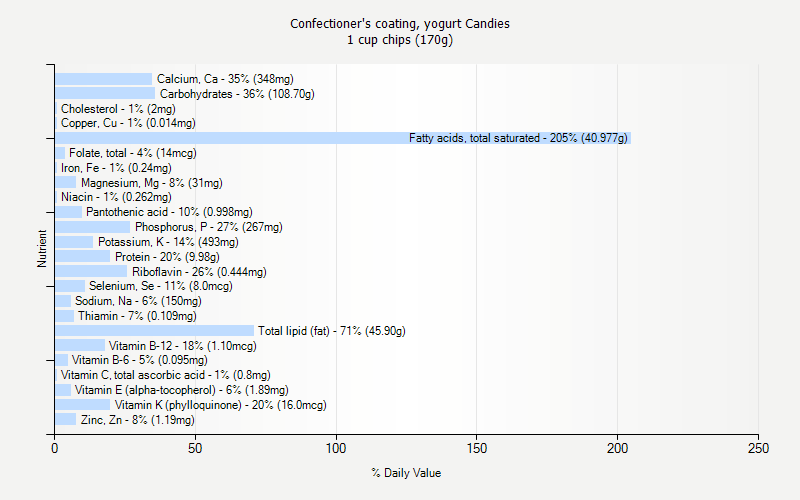

Confectioner's coating, yogurt Candies nutrition

Confectionery Coatings. Blommer offers a wide variety of compound coatings made with specialty vegetable fats to optimize coating performance while delivering the desired flavors. Offered in a variety of flavor profiles, particle size, viscosities and colors to meet your every need. Milk Coatings. Dark Coatings.

White Confectionery Chocolate Coating — ifiGOURMET

Vanilla candy coating, also known as almond bark or confectionery coating, is a type of sweet covering that is primarily used for coating and dipping various confections such as cookies, cake pops, and pretzels. It is a popular alternative to traditional chocolate as it is easier to work with and does not require tempering.

Aluminium Powder Coatings Top Powder Coating Company

Looking for Merckens chocolate melts? We carry only the best in chocolate and candy coatings! Great for melting in molds, Merckens is a high-quality candy melt that tastes delicious and melts smooth!

Confectioners Sugar Replacement by Swerve Thrive Market

Cumberland Dark Confectionery Coating. Flavor Profile: Strong baked brownie and mildly sweet. Performance. Products formulated to support a particular functionality in process or finished product such as with a quick and easy melt with optimal mouthfeel, our Performance line will get you covered.

Things I Like To Make Homemade Chocolate Covered Cherries

Important to note: Don't get confused with the different names! Candy coatings, candy melts, chocolate melts, confectionery coatings, and compound coating wafers all mean the same thing. These are all terms used to describe this type of chocolate. Candy coatings are not REAL chocolate, they do not contain cocoa butter but instead palm kernel oil.

Dark Chocolate Compound Block 2.5kg Falcon's Eye Marketing L.L.C

Heat 1" of water over low heat in a saucepan. Place a bowl over the saucepan, being sure the bottom doesn't touch the water. Put chopped chocolate, wafers, or chips in the bowl and stir occasionally until melted. This process is slow. Do not raise the temperature to speed things up.

Confectioners Glaze 280ml by Cake Craft Company

Log House Foods has been developing and refining confectionery coating for over 50 years. Our focus on improving the consumer's experience is what has led to CANDIQUIK® Coatings. Log House CANDIQUIK® Coatings, like almond bark, can be used for home candy making as well as countless other applications. All CANDIQUIK® Coatings are packaged.

White Confectionery Coating Wafers S586 50lb The Grain Mill Coop of

Watch on. Chocolate candy coating, also known as confectionery coating or almond bark, is a type of chocolate that is specifically formulated for melting and covering candies, cookies, and other treats. It is often used as a substitute for real chocolate in recipes because it is easier to work with and does not require tempering.

Candies, confectioner's coating, peanut butter BodBot

How to melt confectionery coating using an electric skillet? Fill an electric skillet with some hot water and set the temperature to "WARM" (or the lowest setting). Fill glass jars, coffee mugs, or ramekins with the confectionery coating wafers. Place the jars in the water-filled skillet. Make sure the water comes up about halfway on your.

Purple + Matte Clear powder coating. Learn to powder coat at http//www

For the product developer, a sound understanding of what confectionery coatings are and how they behave will lead to an understanding of which coating best suits the intended application. Peter Dea is a product development group manager for Mattson & Co., Foster City, CA, ( www.foodcom.com ), an independent developer of new food and beverage.

How to Make Frosting Using Evaporated Milk Frosting Recipes & Designs

White candy coating is a popular alternative to chocolate in baking and confectionery, made with sugar, vegetable oils, milk solids, lecithin, and flavorings. It is smoother and creamier in texture compared to chocolate, and can be easily melted and molded into various shapes without the need for tempering.

Dowanol PM Solvent Coatings Household Cleaner Industrial Solvent 5

Perhaps one of the reasons so many manufacturers want their coatings customized is that confectionery coating applications vary, from enrobing a candy bar to coating a doughnut and everything in between, explains Fine. "More and more, customers are seeking customized products tailored to their specific needs," he says.

Elastomeric coating actually is an abovegrade roof or exterior wall

Here's what you need to do: Measure the sugar, corn syrup, and water precisely to ensure the right consistency and texture of the candy. Place the saucepan over medium heat and stir the ingredients until the sugar dissolves completely. Use a candy thermometer to monitor the temperature.