Precision tool and die maker Tool and die maker, Manufacturing

Tool and Die Maker Apprenticeship Northcentral Technical College

A machinist at a lathe Tool and die makers are highly skilled crafters working in the manufacturing industries. Variations on the name include tool maker, toolmaker, die maker, diemaker, mold maker, moldmaker or tool jig and die-maker depending on which area of concentration or industry an individual works in.

Precision tool and die maker Tool and die maker, Manufacturing

Tool and die makers are skilled artisans who enter their careers after a combination of education and hands-on training. This online Tool and Die Maker course is the perfect way to get started in your new career as a tool and die maker. This course provides an intensive overview of the skills necessary for tool and die making.

Tool & Die Maker Brunk

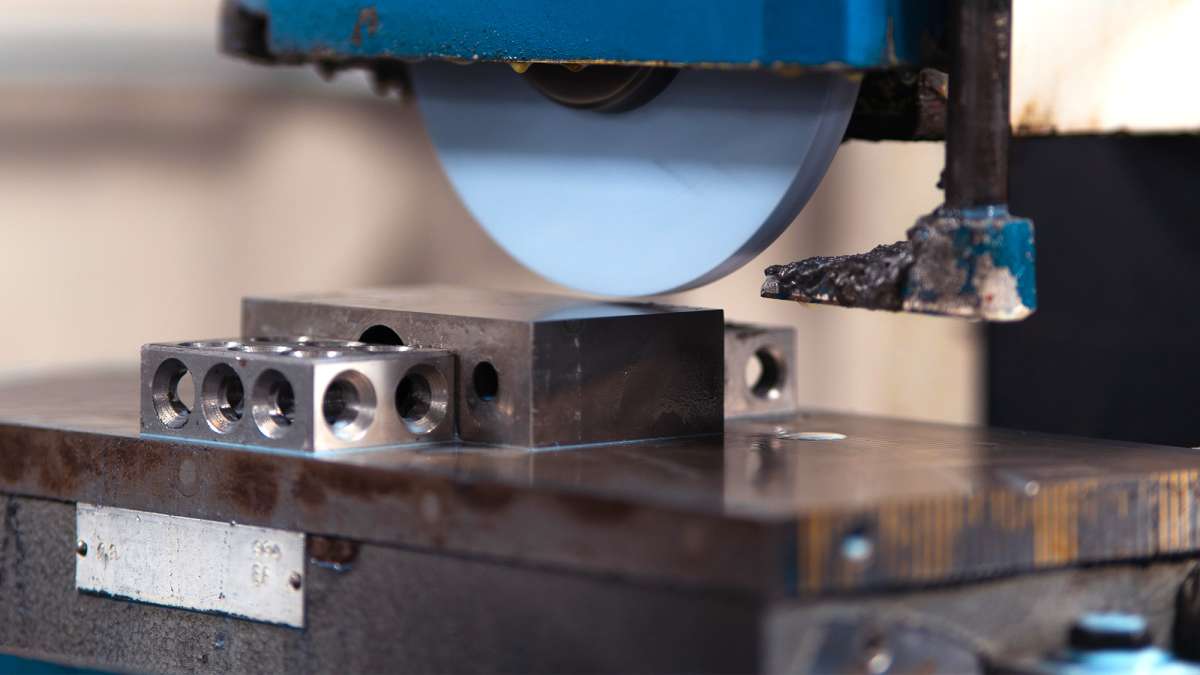

Tool and Die Maker Download: Job Summary: The Tool and Die Maker will cut, shape, finish, and maintain tools made of metal and will forge diecasts to create molds. Supervisory.

What is Tool and Die Engineering? Atlantic Tooling & Fabricating Company

Tool and Die Makers: Read blueprints, sketches, specifications, or Computer-Aided Design (CAD) or Computer-Aided Manufacturing (CAM) files for making tools and dies. Compute and verify dimensions, sizes, shapes, and tolerances of workpieces. Set up, operate, and disassemble conventional, manual, and computer numeric controlled (CNC) machine tools.

Tool&Die manufacturing Btec Solutions

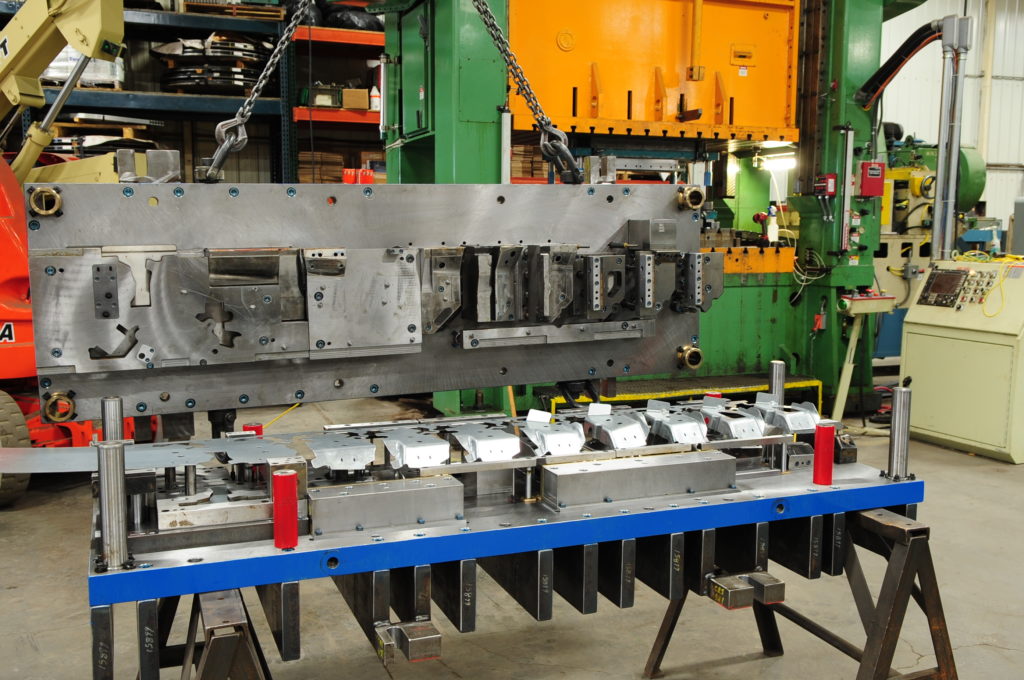

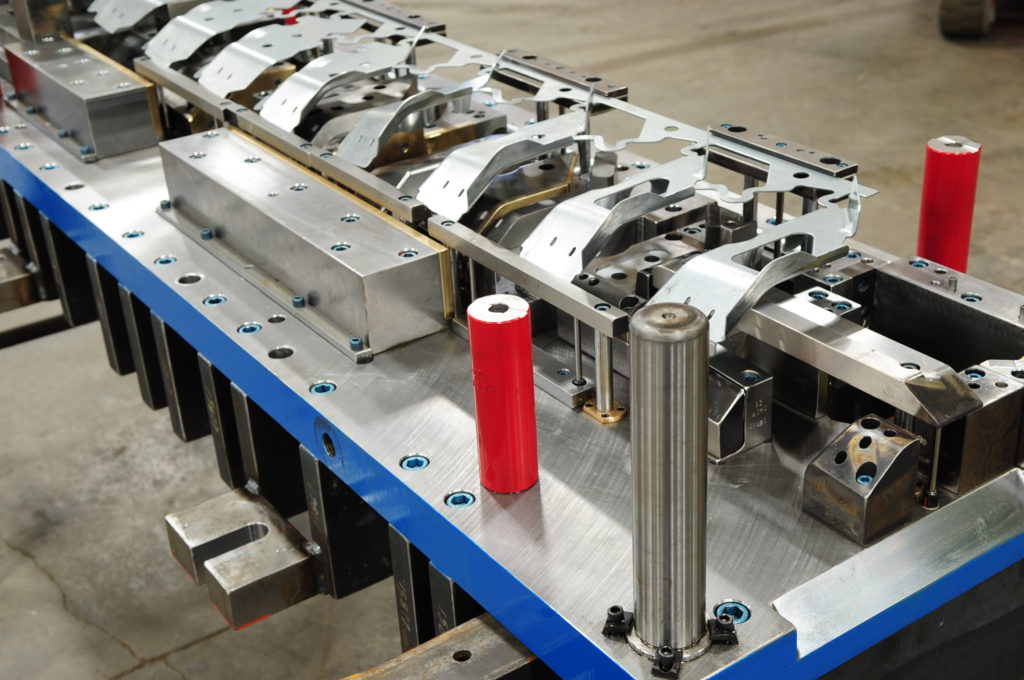

Die makers also perform periodic die maintenance and service to ensure continued performance over the lifetimes of the dies. One of the most challenging problems faced by tool and die makers: the increasing complexity of parts. Advances in technology and engineering have resulted in more intricate products that require more precision in their.

Tool & Die Makers Tooling Engineers ESI Engineering Specialties Inc.

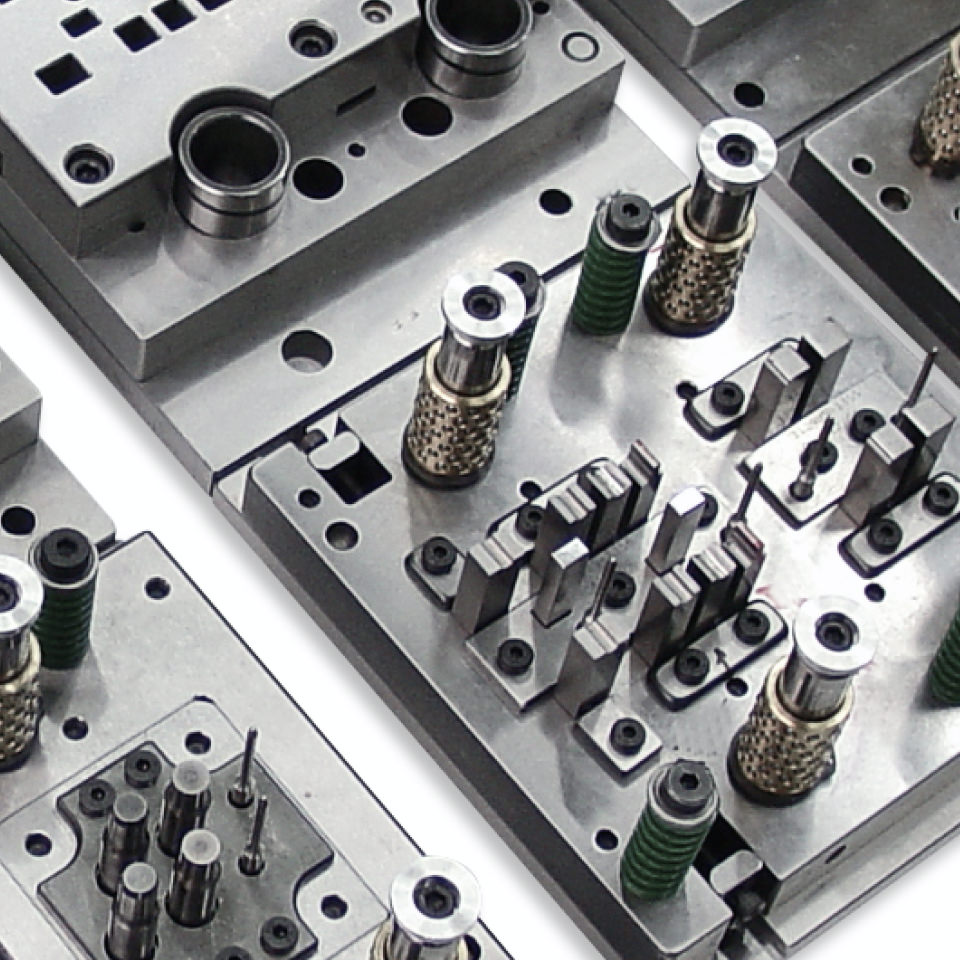

ESI tool and die makers bring decades of experience to every aspect of the job. Using wire EDM, 5-axis CNC, and other high-precision equipment, they achieve tolerances as tight as .0005" (.01 mm) for parts and .0002" (.005 mm) for dies. Producing one part can require a number of tools and a lot of skill.

Vortool Manufacturing Ltd.

A tool and die maker can create and fix metal forms that make metal or plastic parts that create objects we use every day. A career as a machinist and tool and die maker is endless, spanning from maintaining industrial machines to making the die that forms your favorite video game controller.

Tool and Die Progressive Stamping Dies Oberg Industries

51-4111.00. Analyze specifications, lay out metal stock, set up and operate machine tools, and fit and assemble parts to make and repair dies, cutting tools, jigs, fixtures, gauges, and machinists' hand tools. Sample of reported job titles: Die Machinist, Die Repair Laborer, Die Repair Technician (Die Repair Tech), Jig and Fixture Repairer.

Tool and die maker Artofit

State & Area Data Explore resources for employment and wages by state and area for machinists and tool and die makers. Similar Occupations Compare the job duties, education, job growth, and pay of machinists and tool and die makers with similar occupations.

Tool & Die Making Die Makers Manufacturing

Tool and die manufacturing is a machining method used to create a variety of implements that are important in various manufacturing processes. The term "tool" refers to instruments utilized in fabricating other parts, while "die" creates intricate shaped objects in the same way as a mold.

Die plate preparation Metal stamping dies, Metal stamping, Tool and

Becoming a tool and die maker involves a combination of education, training, and practical experience. Here's a general roadmap to follow: High School Diploma or Equivalent: Start by obtaining a high school diploma or GED. Focus on subjects like mathematics, physics, and mechanical drawing, as they provide a strong foundation for the field.

What Do Tool & Die Makers Actually Do? Cav Tool Co.

A Tool and Die Maker designs, creates, repairs and tests prototypes and production tools such as dies, cutting tools, jigs, fixtures, gauges and specialty tools using various metals, alloys and plastics. Specifically, a Tool and Die Maker: reads and interprets complex engineering drawings, tooling drawings and work-process documentation

What is Tool and Die Making? YouTube

72 piece Tool and Die maker Tools Inside outside cutter Please look description Pre-Owned $215.00 Top Rated Plus or Best Offer mastertiny (5,775) 100% Free shipping Free returns Diamond & CBN Tooling for Grinding, Machinist, Mold Maker, Prototype Work 21 Pcs Pre-Owned $43.64 allofthethings4u (2,619) 100% Buy It Now Free shipping

Tool & Die Making Die Makers Manufacturing

A tool and die maker specializes in designing, crafting, and maintaining precision tools, dies, molds, and fixtures used in the manufacturing process. These professionals play an important role in industries such as automotive, aerospace, electronics, and more, where precision and accuracy are paramount.

Odds and Ends 49 A collection of Tool and Die Maker Tools YouTube

tool and die making, the industrial art of manufacturing stamping dies, plastics molds, and jigs and fixtures to be used in the mass production of solid objects.. The fabrication of pressworking dies constitutes the major part of the work done in tool and die shops. Most pressworking dies are utilized in the fabrication of sheet-metal parts that range in size from the finger stop on a dial.

Career as a Tool & Die Maker What They Do AJAC

Die Makers Manufacturing is an experienced tool and die shop that designs and builds tools and dies. At our state-of-the-art facility we continue to reinvest in the latest equipment and software. As a result, our clients receive the lowest cost per part, the highest quality, and on time delivery.