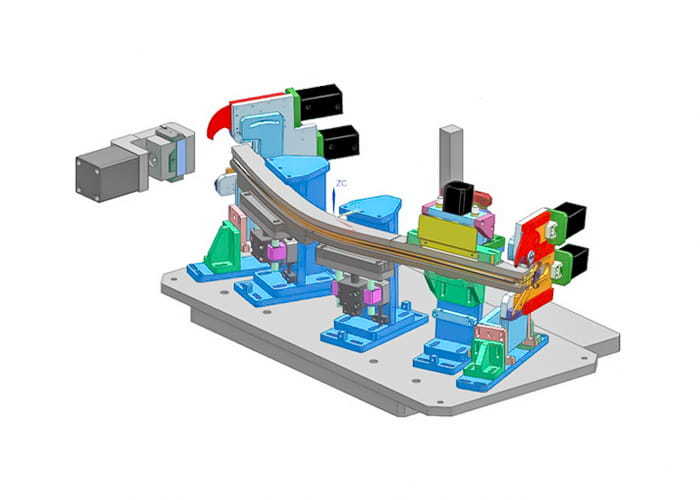

OEM OEM Car part stretch bending mold Manufacturers, Factory

Profile Stretch Bending Machine, Stretch Forming Machine Supplier in

A chronological overview of the historical facts of the art of hand weaving, with an emphasis on the development of large and complex patterns is provided. The development of looms or weaving machines through history for weaving fabric with large patterns is described. Hand weaving complex patterns from primitive weaving on frames to more complex weaving with two weavers operating one loom was.

Rollbending and stretch bending MS Industrie

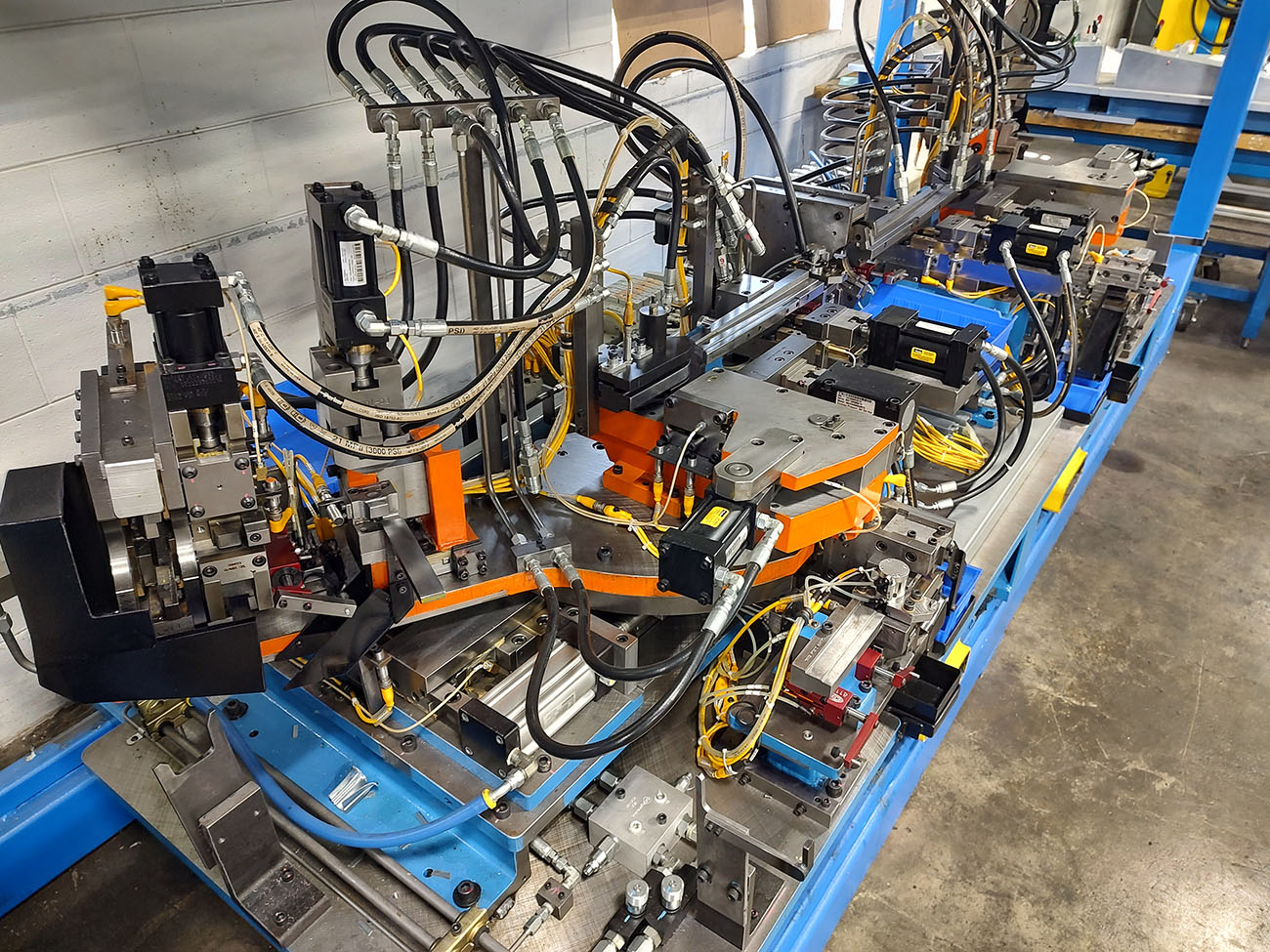

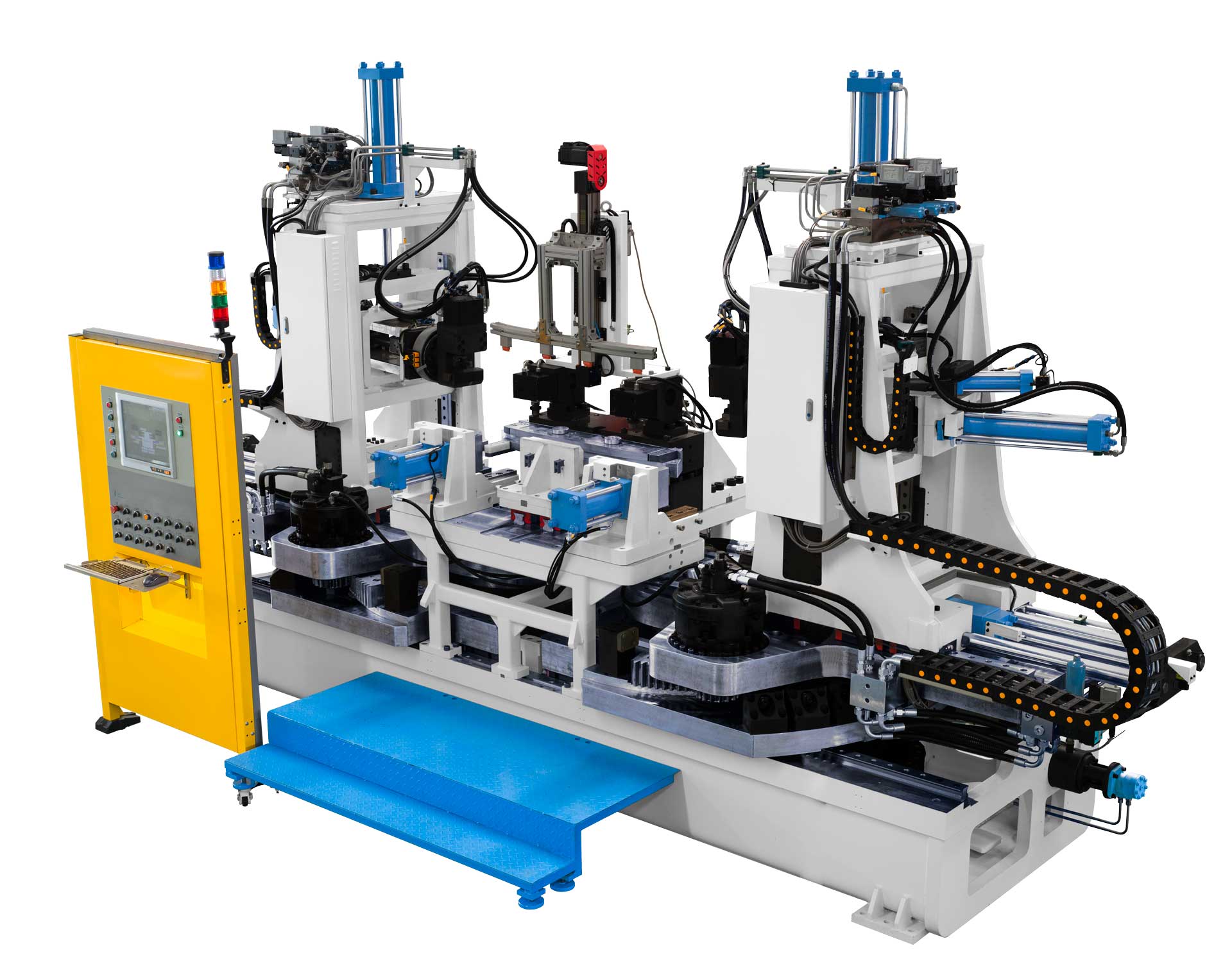

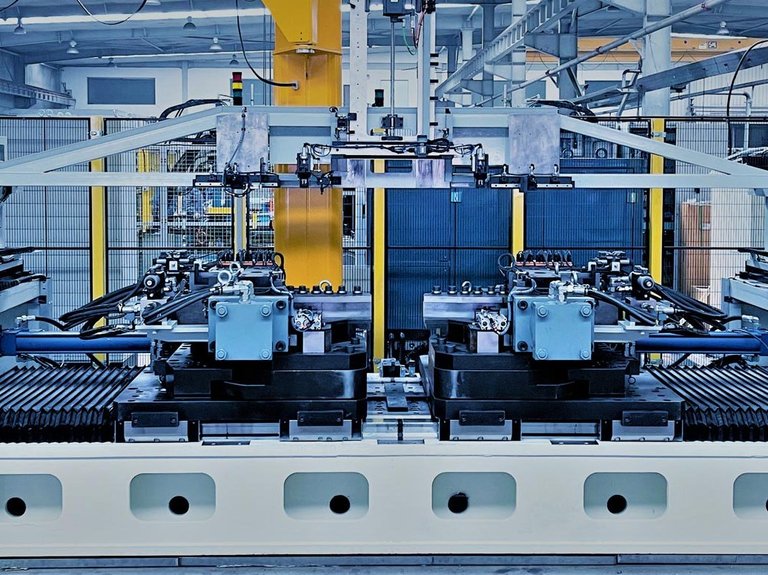

Our portfolio ranges from manually operated CAM bending machines to automatic machines with 16 NC axes, which can be used for various products with stretching force from 2o to 1.000 kN. FSM machines can process 2D bent parts as well as very complex 3D bent parts made of aluminum, steel, stainless steel or high-strength steel.

OEM OEM Car part stretch bending mold Manufacturers, Factory

One of the many fabrication services Alexandria Industries provides customers is precision stretch forming and bending of aluminum extrusions to create your product's components. Different methods of bending and stretch forming will deliver different results. We help customers understand these differences by educating them on the best bending.

stretch bending MS Industrie

Stretch-bending achieves its superior results by maintaining constant tension to the workpiece, stretching and then bending or forming it while under tension. The workpiece is pressed onto or around a machined form (a die, also called a form block) to achieve a part with one or several different curve radii.

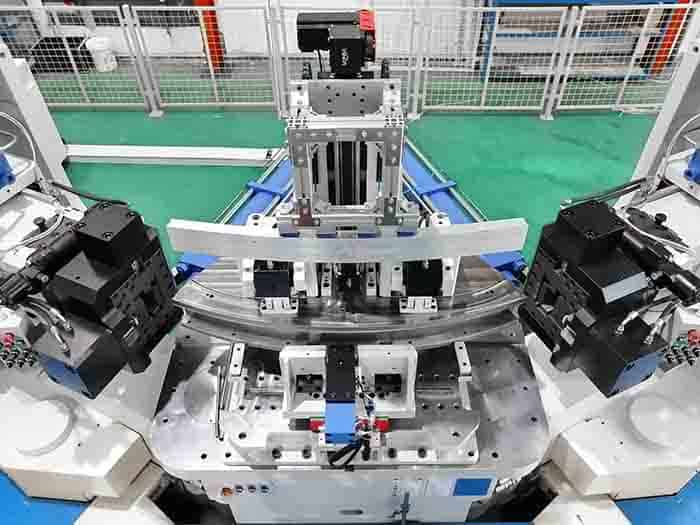

1200MPa high strength steel stretch bending machine (Bumper Beam) YouTube

Stretch Forming Machines are a game-changer in metal fabrication, offering a versatile solution for all markets. From aerospace and automotive to architecture and industrial sectors, these machines excel in shaping complex curves and intricate profiles with precision and efficiency.

Stretch Bending Metal Forming Process

Extrusion stretch forming machines are used to produce extruded structural components with complex cross sections and curved profiles such as stringers and support beams for aircraft, skeletal components for locomotive, buses, transportation structures, and various curved shapes used in the elevator and architectural (building) industry.

OEM OEM Car part stretch bending mold Manufacturers, Factory

FSM Automation Advanced Solutions for Manufacturer Stretch Bending, Roll Forming, Stamping, Sealing, Notching, Automated Integration & Molding.. With this knowhow, we develop and manufacture systems, machines and equipment that are essential in the production of battery trays, crash management systems, body structural parts, body seal parts.

stretch forming & stretch bending machineG Clef A2D55T CNC torsion and

Tube hydroforming is a special process which utilizes a liquid medium to form the tube into required shape. This method has an advantage of attaining uniform pressure all through the tube at any time throughout the process. The forming limit curve (FLC) of SS 304 tubes at different annealed temperatures viz., 150 °C, 200 °C and 250 °C were investigated and compared with as received.

Stretch Forming Machine for Sale roll bending machine stretch

Del Williams - October 15, 2023 The stretch forming process can create stronger parts, increase production, and reduce processing steps, but selecting a machine with best-in-class capabilities is essential. PDF

Stretch Bending Metal Forming Process

Stretch bending is a popular forming technique aiming at forming the long product's axis into a desired curvature with the cross-section remaining constant. The most efficient and convenient method to prevent the defects in stretch bending such as axial springback and cross-sectional distortion is the optimization of forming path.

Profile Stretch Bending Machine, Stretch Forming Machine Supplier in

Capacities: Stretch bending technology allows us to bend: Tubes and sections up to 500mm in width. Aluminium extrusion profiles, aerofoil louvres, steel and stainless steel tubes and sections. Tubes and profiles with a maximum length of 13 meters. Additional services like machining, welding and heat and surface treatments (incl. wood finish)

stretch forming machine roll bending machine stretch forming

Stretch forming is a type of metalworking most commonly used in aerospace applications. During the metal stretch forming process (also known as 'wrap forming'), metal sheets or extrusions are stretched to exceed their inherent elastic limit and formed around contoured dies to create the desired shape.

Cyril Bath V20 Stretch Form USA Kitmondo

From the textile manufacturers' point of view, coarse and medullated fibers are undesirable in the production of fine woolen materials, but highly desirable in the production of textiles and yarns with special effects, especially in carpet production. For sustainability, the entire sheep fleece should be used, including the coarse and medullated fibers. The raw wool must be scoured to obtain.

FSM Group Stretch Bending

An Introduction. Stretch forming is a metal forming process that simultaneously stretches and bends a selected material over a machined form, called a die, to form a part with one or several different curve radii. This process produces perfectly curved parts with smooth, wrinkle-free contours. The aerospace industry initially invented the.

stretch forming & stretch bending machineCNC for automotive bumper

1 Introduction. Embodiments of stretchable electronics enable a wide range of applications from implantable (bio-) electronics, [] autonomous wearable devices, [] to electronic skins for soft robotics. [] The transformation from rigid to flexible and ultimately stretchable devices is typically achieved by utilizing intrinsically stretchable materials or through structure-enabled (rigid-island.

200 Ton Sheet Stretch Forming Press YouTube

How to Pick the Right Stretch Former Machine Based on Application | New Equipment Digest Select the right stretch-former with ease by learning the basics of stretch-forming equipment including the different types and designs, how to identify which ones will last for.