Garde Commercial French Fry Cutter 3/8" WebstaurantStore

手数料安い モリコーYahoo 店Newhai Commercial French Fry Cutter Manual Potato

30 min cool: Leaves fries to cool for 30 minutes. Line a large bowl with paper towels - for draining and tossing. Fry #2: Heat oil to 205°C/400°F. Fry half the French fries for 4 minutes, moving them around twice, or until golden brown and crispy. Drain in the lined bowl, then repeat with remaining fries.

Top 10 Best French Fry Cutters in 2023 Reviews Buyer's Guide

Freeze the potatoes as quickly as possible. Remove the excess oil covering the fries in a de-fatter. The vibrating tray shakes the unabsorbed oil off the strips and recovers it for new frying cycles. The chips are now ready for freezing. Bring their temperature down in a cooling chamber, then freeze to a temperature of -12°C.

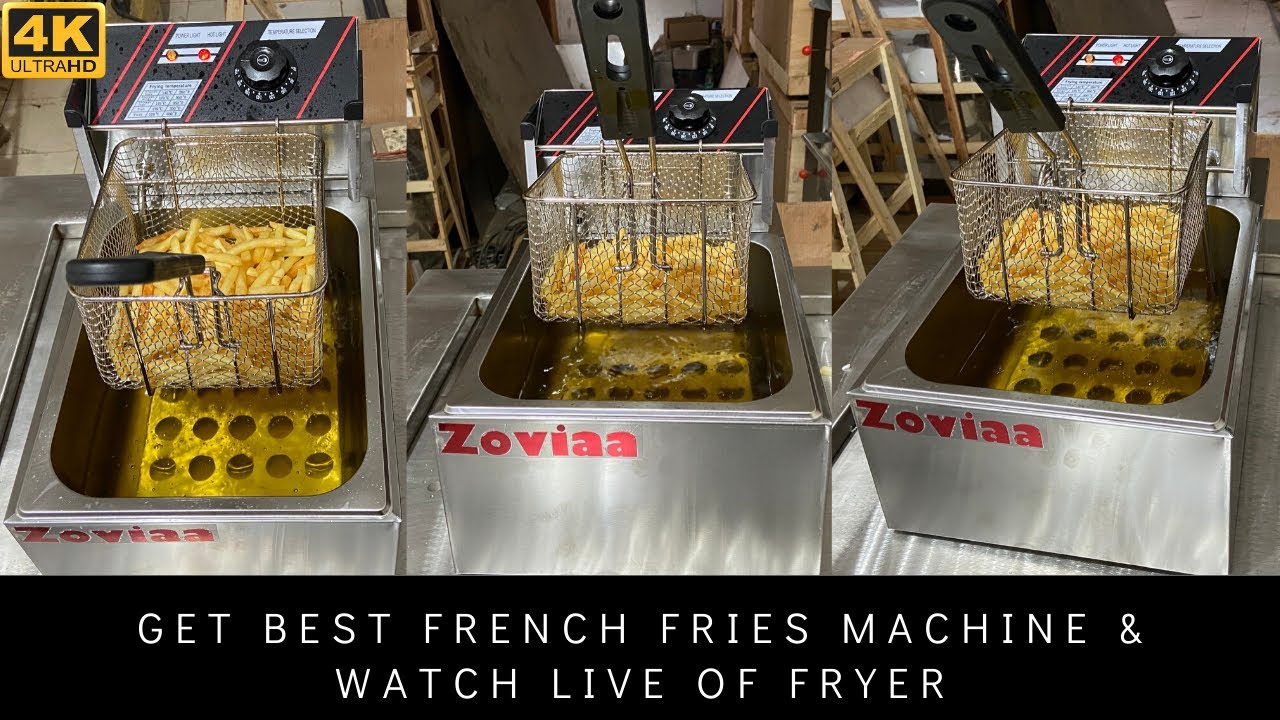

French Fries machine Electric Fryer AS81 Demo YouTube

Manual French fry cutters are all built along much the same lines. A frame supports a sliding mechanism with the blade at one end and a handle attached to a pusher block at the other. Pull the arm, which forces the pusher block down the slider to the awaiting blades, and the potato is sent through the blade, cutting it into french fry lengths.

French Fry Cutter, Potato Cutter, French Fry Cutters

Instructions. Wash then peel (optional) the potatoes. Cut the potatoes using a fry cutter or knife to get that classic fry shape. Soak the potatoes in a large bowl of cold water with a few tsp. of salt for 20 to 30 minutes. This briny water will remove the starch from the potatoes.

Fast food counter top french fries station for kitchen equipment, View

Contents hide 1 French Fries Business Opportunity Worldwide 2 Full Equipment for Making French Fries 3 Commercial Potato Washer 4 French Fry Cutter 5 Potato Chips Blanching Machine 6 Potato Chips Frying Machine 7 Dewatering Machine for Finger Chips 8 French-Fried Potatoes Deoiling Machine 9 Vacuum Packer for French Fries Making Business

French Fries Machine Stock Photo Getty Images

french fries production machines . For complete french fries solutions, there's no better choice than tna.. tna helps customers by providing complete processing and packaging solutions to create the ultimate french fry products from a single source. As your partner, we bring more than 40 years of innovation, french fry production experience, and a global network of experts in more than 30.

French Fry Potato Heavy Duty Fries Maker Vegetable Cutter Professional

French Fry Cutter - Potato Slicer. Save time preparing French fries and other potato recipes by choosing the right cooking tools for the job. Choose between plastic, solid metal, or mandoline slicers. French Press Coffee Pot. This is a great way to get a European style coffee without a lot of fuss or expense.

Garde Commercial French Fry Cutter 3/8" WebstaurantStore

A Manufacturers Guide to Cleaning Your Fryer - English. PDF. How to select the right metal detector - English. PDF. Heat and Control is a leading industrial potato equipment manufacturer capable of processing a large variety of french fry and formed potato products.

Chef is Cooking French Fries in the Kitchen, Chef Cooking Fried Potato

December 7, 2020 @thecooksatelier Read Next Here are the best French kitchen utensils and cookware to cook like a chef! If you're looking to become a better cook and master the French classic recipes, then you need the right equipment. And unsurprisingly, the French don't mess around when it comes to kitchenware.

French Fries Warmer Fast Food Equipment French Fries Display Warmer

Equipment for the production of french fries and other potato snacks usually includes: - Washing machine Washing of root crops can be carried out in equipment with various different modifications and cost. It mostly depends on the degree of contamination of the potato or other root vegetables.

Home kitchen stainless steel environmental frying french fries frying

700-2,000 kg/hr. Suitable for the small-scale french fries plant. Suitable for washing and peeling kinds of root vegetables. It can do dry and wet cleaning, with flexible spray nozzles. SUS304 stainless steel frame. Top quality durable nylon brushes. Easy to operate, potato peeling time and speed are adjustable.

11.7L 1500W Commercial Electric Deep Fryer Machine Countertop

The equipment needed for a French fries business can vary but can include a commercial-grade deep fryer, a potato peeler, a food processor, and a holding station. These pieces of equipment can be costly, but they are essential for producing high-quality French fries that will keep customers coming back.

ITOP Double Tank Electric Deep Fryer Machine Stainless Steel French

FAM's cutting equipment for French fries includes the Tridis 240P, a tridimensional dicer, designed for the French fry industry. The company states that compared to other available cutting machines, the dicer increases capacity by 10% to 40%. The development process for this equipment was done in cooperation with the company's industry.

HOT Stainless Steel Kitchen Tools household french fries knife shredder

Description. Heat and Control is BIG in french fries: Over 16,000 kg/hr. of finished crispy batter-coated french fries can be produced for fast-food lovers using Heat and Control's latest batter applicator and multi-zone fryer system. The batter applicator applies a clear coating that gives fries a crisp texture and long serving life.

Best French Fry Cutter For Home Use 11 Explore top designs created

Here are some of the most common types with a comparison of the four varying materials below: Paper Melamine Stainless Steel Copper-Plated Metal Bamboo Disposable French Fry Holder Sizes While holders come in a variety of sizes, most often disposable ones offer the same type of holder in small, medium, large, or extra-large sizes.

Stainless Steel Mini Square Fry Basket French Fries Holder

Vanmark is the equipment for choice for high-volume french fry lines. We've worked with the largest brands for decades to optimize our equipment for making top-quality fries. And we bring that expertise to every one of our customer projects. Our machines significantly increase production, minimize waste, and automate manual processes and labor.