What is TMT Bar(Thermo Mechanically Treated Bar)Why TMT bar is used,How TMT bar is Produced

What is Thermo mechanical Treatment in Steel? Shyam Steel

Encyclopedia of Materials: Science and Technology The purpose of TMT is to provide, by selective control of temperature and forming conditions, a final product with material properties which this particular material would never be able to reach under conventional production methods.

Thermo Mechanically Treated Bars at Rs 42/kilogram Mild Steel TMT Bars in Mumbai ID 13354065148

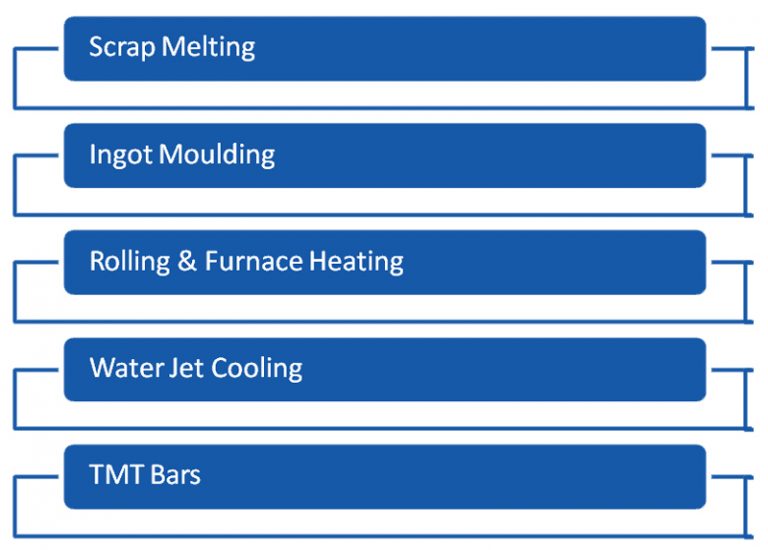

Reinforcement bars (rebars) are thermo-mechanically treated (TMT) products with a microstructure comprising a tempered martensite at the periphery and a ferrite-pearlite structure at the core. Billets made from scrap and direct reduced iron (DRI) were hot rolled (HR) to produce TMT rebars.It has been observed that, there is correlation between.

Thermo Mechanical Treatment

1. Introduction Reduced activation ferritic martensitic (RAFM) steel is considered as the most favoured structural material for the plasma facing test blanket module in fusion reactors due to its low activation and superior resistance to radiation induced swelling [ [1], [2], [3]].

Thermo Mechanically Treated TMT Bars, For Construction, Grade Fe 500 at Rs 44/kg in Kolkata

550D or Fe 550D TMT Bar is a grade of Thermo Mechanically Treated (TMT) steel bars, as defined by IS:1786, with Fe being the symbol for the Iron. Iron is the primary metal that the bars are made up of. '550'denotes the minimum yield stress in MPa (the tensile stress required to produce a total elongation) and the letter 'D' denotes ductility.

Mild Steel 6 mm to 40 mm Thermo Mechanically Treated Bars, For Construction, 6 18 Meter at

Types of Thermo-Mechanical Treatment: i. Isoforming: It is a thermo-mechanical treatment in which the metastable austenite is deformed while it is transforming to ferrite- pearlite, or bainite as illustrated schematically in Fig. 9.1 (c) and (d) respectively.

Low and High temperature thermomechanical treatments

Thermomechanical processing is a metallurgical process that combines mechanical or plastic deformation process like compression or forging, rolling, etc. with thermal processes like heat-treatment, water quenching, heating and cooling at various rates into a single process. [1] Application in rebar steel

Thermo Mechanically Treated TMT Bars at Rs 33500/metric ton Aditya TMT Bars, Ankit TMT Bars

Deformation mechanisms Phase transformation Microstructure Mechanical properties 1. Introduction Optimizing the elusive strength-ductility trade-off and developing alloys with a superior combination of strength and ductility are important challenges to meet the demands of various engineering applications [1, 2 ].

THERMO MECHANICALLY TREATED (TMT) BARS YouTube

Thermo-mechanical treatment is the simultaneous application to steel that involves heating and cooling. It is to develop better properties in steel by refining its micro structure. This heating technology is referred as hot rolling in this process vast quantities of steel can be handled.

What is TMT Bar(Thermo Mechanically Treated Bar)Why TMT bar is used,How TMT bar is Produced

The resulting refinement of the grain size produced a dramatic increase in strength for the thermo-mechanically-treated HEAs. It was found that the thermo-mechanical treatments also led to the formation of precipitates, which are shown to both slightly increase the yield strength and decrease the ductility. TEM studies were used to determine.

Iron Jindal Thermo Mechanically Treated Bar For Construction at Rs 42/kg in Chennai

Thermo Mechanically Treated (TMT) steel bars are high-strength reinforcement steel bars used in construction projects, including residential, commercial, and industrial projects. They are in everyday use in the construction of buildings, bridges, dams, and other infrastructure projects where strength and durability are essential. TMT steel bars feature high yield strength and good ductility.

Thermomechanical treatment carried out on all the alloys. Download Scientific Diagram

Thermo-Mechanically Treated Bars, (TMT Bars), are Extra High Strength Reinforcing bars which replacing any form of cold twisting, the technology of yesteryears. In this process, the steel tmt bars receive a short, intensive cooling as they pass through the specially resigned Tempcore Water Cooling System after the last Rolling Mill Stand.

Thermo Mechanically Treated Tmt Steel Bars Stock Photo 1943887786 Shutterstock

This text is designed for use by graduate students coming into the field, for a graduate course textbook, and for Materials and Mechanical Engineers working in this area in the industry. Purchase Thermo-Mechanical Processing of Metallic Materials, Volume 11 - 1st Edition. Print Book & E-Book. ISBN 9780080444970, 9780080544489.

Thermo Mechanically Treated TMT Bars, For Construction, Grade Fe 500 at Rs 44/kg in Kolkata

S. Bremmer, V. Flaxa and F. M. Knoop, "A Novel Alloying Concept for Thermo-Mechanical Hot-Rolled Strip for Large Diameter HTS (Helical Two Step) Line Pipe," Proceedings of IPC 2008, 7 th International Pipeline Conference, Sept. 29 — Oct. 03, 2008, Calgary, Alberta, Canada. Google Scholar

Thermo Mechanically Treated TMT Bars, For Construction, Grade Fe 500 at Rs 44/kg in Kolkata

Exploring 36 Types of Thermomechanical Treatment. August 28, 2023 / By Shane 19 minutes of reading. The process of deformation heat treatment is commonly referred to as "thermo-mechanical processing.". In the field of machinery manufacturing, the combination of pressure processing techniques (such as rolling, forging, and rolling) and heat.

WHAT IS THERMOMECHANICAL TREATMENT IN STEEL? JBG HEXA

What are TMCP (Thermo-mechanically Controlled Processed) steels? The mechanical properties introduced to the steel through this processing route are virtually equivalent to those obtained by heat treating conventionally rolled or forged steel. TMCP involves controlled hot working and microalloyed steel compositions.

What makes Thermo Mechanically Treated bars so special? Agni Steels Official Blog

In the heat treatment of wood above 150°C, the strength is reduced and the mode of failure of heat-treated wood in mechanical tests is in most cases brittle. The density of wood is decreased by 5-15% during heat treatment, and this of course affects the strength, but it does not explain the entire reduction in strength (see Welzbacher et al.